There are four models currently in production: The Osprey, The JB Special, a Fretless banjo, and The Hornbeam Special.

These banjos are based on a beveled rim assembly similar to that developed by Rettburg and Lange around 1898 and sold under the A. A. Farland label. Alfred A. Farland was possibly the greatest classical banjoist. He had originally been a strong supporter of S. S. Stewart, but by 1897 he had left the Stewart camp and was working with the Rettburg and Lange Company to develop his own banjo. The Rettburg and Lange Company was based on the remnants of the bankrupt Buckbee Banjo Company. In 1898 the Farland Top Bevel Wood Rim banjo was introduced. This banjo featured a thick rim of 3 to 5 plies of steam bent Maple. On some models a thin veneer of Birdseye Maple was used inside and outside. A number of sizes were available from 10 1/2 to 12 1/2 with the appropriate scaled neck in a variety of styles from plain to fancy.

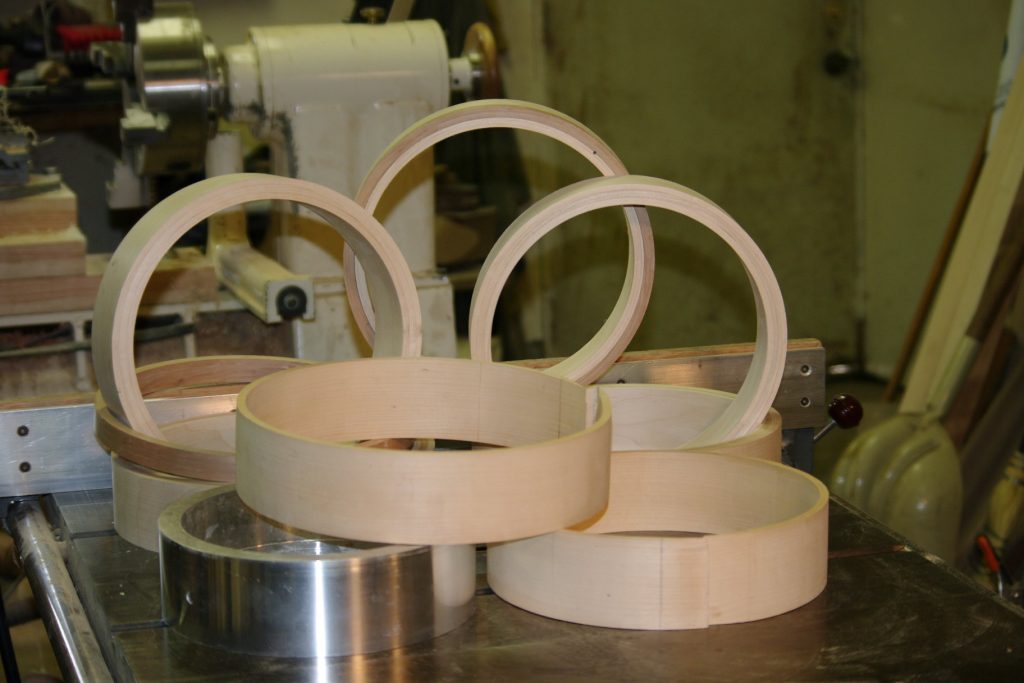

Each Bloom banjo has a thick, hand-built, steam-bent rim of select hard Maple. The individual slats are steamed and bent, then kiln tempered to set the bend. The first lamination is secured, glued and trued on an aluminum rim form. The subsequent laminations are glued then trued as well. Truing each lamination provides for the stable and solid rim required to produce the ideal tonal response. I am currently building 3 and 4-ply rims and find no tonal difference.

Every instrument is built by hand. All have similar features such as necks built of book matched Hard Maple with a black center stripe and of course the thick heavy top beveled rim with a bottom cap of Birds Eye Maple.

Neck shaping is done by hand and is based on the White Laydie and Regent banjos built by the Fairbanks Banjo Company around 1901-1910. The necks are built of book matched Hard Maple with a black center stripe. The grain of the neck is chosen to be almost perpendicular to the Ebony fingerboard. I use a 25 1/2 inch scale which will allow for tuning up to “A” with out use of a capo. Machined, ball style Nickel plated brass bracket lugs are used. Nickel plated flat hooks matched to 5/16 open ball end hook nuts and a grooved tension hoop complete the assembly.